About us

About Us

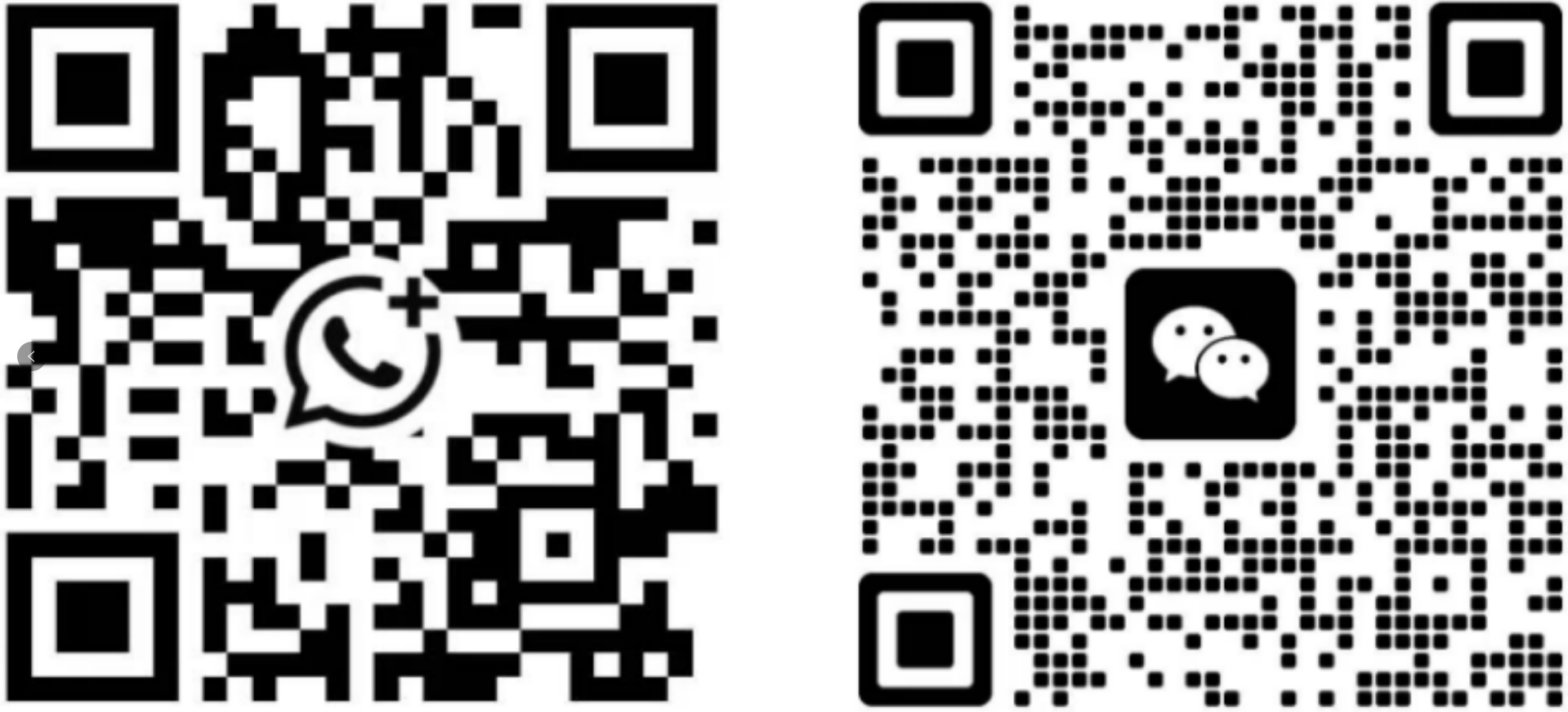

Contact Us

- Tel: +86 186 8960 3020

- WhatsApp:+8619333675988

- 186 8960 3020

- No. 9-1063, Government Street, Beizhen, Shunyi District, Beijing

About us

Start-up (1989-1994)

Beijing Rihua Global Trading Co., Ltd. was officially established in Beijing in 1989. At the time, the automotive parts market was still in its exploratory phase, with many core components reliant on imports. Local companies faced both technological and market challenges. Against this backdrop, the company, with a keen understanding of industry needs, decisively established automotive engine belts, water pumps, tensioners, and timing kits as its core business. This strategic positioning not only allowed the company to avoid the then-competitive general-purpose parts market but also focused on the key engine transmission market segment, laying a solid foundation for subsequent specialized development.

In its early days, the company gradually established a firm foothold in the Beijing market through rigorous quality control and continuous technological research. The team thoroughly researched advanced technologies both domestically and internationally, repeatedly optimizing production processes and striving for excellence in every step, from raw material sourcing to finished product testing. In just five years, the company not only accumulated a stable customer base but also established a mature production and quality control system, building sufficient strength for subsequent cross-regional development.

Expanding Southward (1994-2000)

As business steadily progressed, the Beijing base’s production capacity could no longer meet the growing market demand. At the same time, the automotive industry cluster gradually formed in the Yangtze River Delta region, providing a broader development space for auto parts manufacturers. In 1994, after an in-depth investigation of markets across China—comprehensively evaluating factors such as supply chain support, logistics and transportation convenience, policy support, and labor resources—the company ultimately decided to invest in and build a rubber belt factory in Suzhou, Jiangsu.

The establishment of the Suzhou plant marked the company’s first major cross-regional expansion. Equipped with state-of-the-art rubber processing equipment and production technology, the plant adhered to strict standardized procedures. This significantly increased production capacity for automotive engine belts and further enhanced product quality. With its stable supply capacity and superior product performance, the Suzhou plant quickly gained recognition from leading domestic automakers and the aftermarket.In 1995, the second year after the factory opened, the company received the local Enterprise Excellence and Progress Award for its outstanding performance in technological innovation, capacity expansion, and contribution to the local economy. This honor, while a recognition of the company’s development by the local government, further strengthened the company’s confidence in continuing to cultivate the Yangtze River Delta market and expand its business presence. In the years that followed, the Suzhou factory continuously optimized production efficiency, steadily increasing its market share and becoming a key production base and profit growth point for the company.

Alignment with international standards (2001-2009)

Entering the 21st century, China’s automotive industry entered a golden period of rapid development, with market demand for increasingly diversified and high-quality engine transmission system components. In 2001, the company seized this opportunity and established a tensioner and cooling water pump factory at its Suzhou base. This expanded its core product offering from a single belt to a full range of belts, tensioners, and water pumps, further enhancing its engine transmission system product portfolio.

At the same time, the company actively promoted its “going global” strategy, proactively connecting with the international market. Through technical exchanges and collaborations with renowned international automotive parts brands, the company has thoroughly learned advanced international production management practices and quality standards, continuously optimizing product design and production processes. With its internationally compliant product quality and competitive cost advantages, the company has successfully gained recognition from international brands and launched its OEM business. This breakthrough not only enabled the company’s products to enter the international supply chain but also enabled the team to accumulate experience serving global customers, laying the foundation for future international competition.

That same year, leveraging its technological expertise and industry influence in the automotive engine transmission system field, the company was invited to participate in the drafting of national industry standards, ultimately becoming a national industry standard drafting company. This marked national recognition of the company’s technological prowess and product standards, elevating it from an industry follower to a standard setter, significantly enhancing its voice within the industry. In 2002, the company again received numerous corporate awards from national and local governments for its outstanding performance in technological innovation, market development, and fulfillment of social responsibilities, further solidifying its leading position in the industry.

In 2004, the company turned its attention to the domestic commercial vehicle market. At the time, the domestic commercial vehicle industry was experiencing rapid growth, creating an urgent need for reliable core components. Leveraging its mature product portfolio and consistent quality, the company successfully provided original equipment (OEM) components to leading domestic commercial vehicle manufacturers. Recognized for its timely delivery, superior product performance, and comprehensive after-sales service, the company earned the title of “Excellent Supplier.” This partnership marked the company’s official entry into the OEM market, a significant transition from the aftermarket to the complete vehicle market and further optimizing its business structure.

The brand comes to the fore (2010-2016)

In 2010, with the continued prosperity of the Chinese auto market, domestic passenger and commercial vehicle production capacity increased significantly, and demand for original equipment (OEM) components saw explosive growth. Leveraging its previous success in commercial vehicle components, the company further expanded its OEM business, successfully serving numerous domestic automakers across a wide range of vehicle categories, including sedans, SUVs, heavy-duty trucks, and light buses. To meet the diverse needs of various automakers, the company established a dedicated technical R&D team to tailor product solutions based on the engine parameters of each vehicle model. From product design and prototype production to mass production, the company maintains close communication with automakers throughout the entire process to ensure perfect product compatibility.

With the continuous expansion of its OEM business, the company’s visibility and reputation within the industry have grown. However, for a long time, the company primarily served as a “backstage contractor” or “supporting supplier,” lacking its own independent brand for the end market. In 2011, after an in-depth analysis of market trends, the company realized that building its own independent brand was key to achieving sustainable development. Consequently, the company officially established a brand department and named it “APOLAO,” symbolizing the vitality and strength of the sun, providing reliable powertrain support for vehicles.

To support the market expansion of the “Apollo” brand, the company simultaneously launched a nationwide warehousing strategy, establishing dedicated warehousing centers in core cities such as Beijing, Guangzhou, Chengdu, Jinan, Wuhan, Urumqi, and Shenyang. These centers not only cover seven major regions of North China, South China, Southwest China, East China, Central China, Northwest China, and Northeast China, but also enable efficient collaboration with local distributors.Through localized warehousing, the company can allocate goods promptly based on market demand, significantly shortening delivery cycles and improving customer response times. This move marks the company’s official transition from “behind-the-scenes support” to “front-of-the-scenes brand operations” after 22 years of development, ushering in a new dual-driven development model of “mainframe support + brand retail.”

Once launched, the “Apollo” brand quickly gained market share with its three core advantages: first, the price advantage of factory direct supply, which eliminates the middle link and benefits dealers and end customers; second, the quality assurance of the main engine supporting standards. All products are produced in accordance with the main engine manufacturer’s standards to ensure stable performance and long life; third, the “one city, one generation” regional protection model, which provides dealers with exclusive market space, avoids vicious competition, and guarantees dealers’ reasonable profits.Leveraging these three advantages, the “Apollo” brand rapidly penetrated the market in just a few years. By 2016, it had developed more than 700 dealers in various cities and counties across China, building a nationwide sales network and becoming a highly influential auto parts brand in the domestic automotive aftermarket.

Towards a global stage (2017-2024)

In 2017, the company achieved a breakthrough in the original equipment (OEM) sector, successfully providing OEM services to numerous joint venture automakers. Joint ventures often have more stringent quality standards and technical requirements for parts. Our company’s ability to meet these audits not only demonstrates that our product quality has reached advanced international standards but also signals a further advancement in our partnerships in the OEM sector, successfully entering the domestic high-end OEM market.At the same time, the company actively expanded into the international market, comprehensively optimizing and certifying its products to meet the technical standards and regulatory requirements of the European automotive market. Through unremitting efforts, the company successfully obtained multiple industry standard certifications from European countries, enabling its products to enter the European market and paving the way for subsequent global business expansion.

By 2024, the company will have formed a stable pattern of coordinated development of three major business segments: mainframe supporting, branded operation, and OEM and private label manufacturing:

• Original Equipment Business: We provide customized component solutions for renowned international and mainstream domestic automakers. Our product offerings cover the entire engine and transmission system range, meeting the stringent requirements of diverse vehicle models.

• Branded Operations: Leveraging our warehousing centers across seven regions nationwide, we provide efficient supply and service support to over 700 dealers. The “Apollo” brand has established a strong reputation in the market for its reliable quality and exceptional service, steadily increasing its market share.

• OEM/ODM (Original Label) Business: We provide a comprehensive, integrated service offering encompassing product customization, quality control, brand packaging, logistics and warehousing, and after-sales service to global trading companies. From tailoring product design to rigorously controlling every step of the production process, and ultimately providing personalized brand packaging solutions and global logistics and delivery services, our comprehensive industry chain integration capabilities have made us a high-quality partner for numerous trading companies.

Looking back 35 years

From a small startup in Beijing in 1989 to a leader in the engine and transmission systems segment in 2024, over its 35-year history, the company has remained steadfast in its original aspiration of “building a company on quality and thriving it through innovation.” Every factory construction, every business expansion, and every brand upgrade reflects the company’s precise response to market demand and its unremitting pursuit of technological innovation.

Now, standing at a new historical starting point, the company will continue to focus on technological innovation as its core driving force, continuously improving its product competitiveness and expanding its global market presence. In the OEM sector, the company will continue to deepen its collaboration with domestic and international automakers, exploring the R&D and production of new energy vehicle transmission components. In brand operations, the company will further enhance the international influence of the “Apollo” brand and build a globally renowned automotive parts brand. In the OEM and OEM sector, the company will continuously improve its supply chain services to provide customers with more efficient and high-quality solutions.

After 35 years of navigating challenges and forging ahead, this Beijing-based company has demonstrated with its strength the growth potential and resilience of China’s domestic auto parts companies. In the future, it will continue to maintain its high spirits and write an even more glorious chapter in the global auto parts industry.

All staff of Beijing Apollo Auto Parts Co., Ltd. sincerely serve you