About automotive transmission belts

About automotive transmission belts

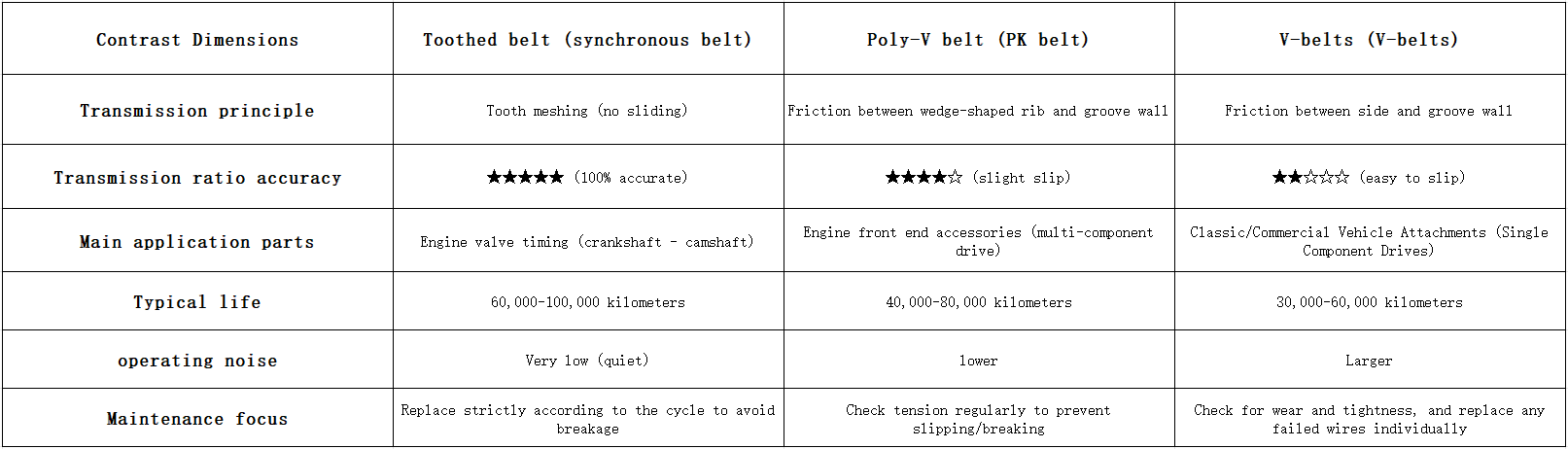

Automobile transmission belts can be divided into three categories: synchronous belts (toothed belts), multi-groove belts (PK belts, serpentine belts), and V-belts (V-belts).

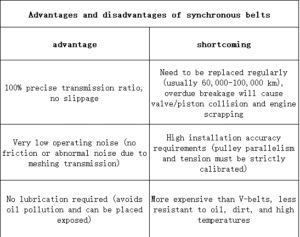

1. Timing belt (toothed belt)

1. Timing belt (toothed belt)

Structural Features: An endless rubber belt with evenly spaced teeth on the inside, typically made of chloroprene rubber (CR) or hydrogenated nitrile rubber (HNBR). Glass fiber or aramid fiber cords are embedded within to enhance tensile strength, and a cloth outer layer is covered to reduce wear.

The key to power transmission lies in the precise meshing of the teeth with the pulley’s grooves, resulting in zero slippage and an absolutely precise transmission ratio (hence the name “synchronous”).

Core Application: Primarily used in the engine valvetrain, connecting the crankshaft and camshaft, strictly controlling the timing of valve opening and closing (also known as “valve timing”), ensuring synchronization of engine intake and exhaust, ignition, and piston movement.

Note: Some new energy vehicles also use high-strength toothed belts to achieve silent transmission between the drive motor and reducer.

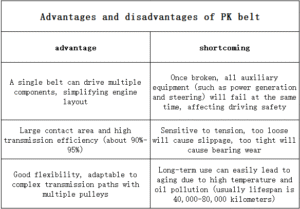

2. Multi-V belt (PK belt, serpentine belt)

2. Multi-V belt (PK belt, serpentine belt)

Structural Features:

It has a flat cross-section with two to six parallel wedge-shaped ribs (“wedges”) on the inside. Its base material is similar to a toothed belt (rubber + fiber cords), and the wedge ribs fit into the wedge-shaped grooves of the pulleys to transmit power.

It combines the high friction of a V-belt with the flexibility of a flat belt, allowing it to drive multiple pulleys simultaneously (“multi-pulley drive”).

Core Applications:

The engine’s front-end accessory drivetrain is the workhorse of the engine, responsible for driving multiple peripheral components, such as:

Alternator (charges the battery and supplies power to the vehicle’s electrical appliances); Air conditioning compressor (provides cooling power); Power steering pump (for hydraulically assisted vehicles, reduces steering effort); Water pump (circulates coolant and dissipates heat from the engine); Air compressor (for some diesel vehicles or vehicles with air suspension)

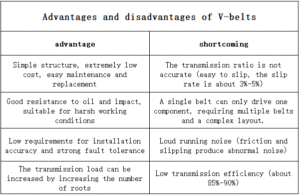

3. V-Belt (also known as “Triangle Belt”)

3. V-Belt (also known as “Triangle Belt”)

Structural Features:

The cross-section is an isosceles trapezoid (“V”), primarily made of rubber with cotton or fiber cords embedded within for added strength. Power is transmitted through friction between the V-shaped sides and the V-groove walls of the pulley (friction increases with tension).

V-belts are available in “standard” (used individually) and “combined” (multiple belts arranged side by side for heavy load transmission).

Core Applications:

The primary drive belt in early automobiles (before 2000), primarily driving single components such as generators and water pumps (which required multiple belts for each drive).

Currently, its use in automobiles has significantly decreased, remaining only in a small number of commercial vehicles (such as trucks and buses) in engines and chassis (e.g., drive shaft auxiliary drives) and construction machinery.